As a premier provider of laser cutting services in China, we specialize in cutting a wide range of materials. Which includes wood, plywood, MDF, plastic, acrylic, stainless steel, aluminum and more to make the custom-made products. Moreover, we offer an array of additional services such as laser engraving, marking, and UV color printing to cater to your specific needs.

Laser cutting has become a mature processing technology, and we have different types and models of laser cutting machines that can provide both non-metal and metal laser cutting services. This enables us to meet your processing needs for different materials. In addition, we have introduced advanced laser engraving machines and large-scale UV printing equipment to simultaneously meet the diverse requirements of our customers.

With the support of the vast Chinese market, we can provide you with better, faster, and more competitive laser cutting services. “Better” refers to the high-quality materials we select as the processing substrates for our respectable customers, as an experienced manufacturer. “Faster” pertains to the convenience of transportation; based on shipment volume and time requirements, we choose different more suitable transportation channels tailored to our customers’ specific circumstances. “More competitive” stems from our comprehensive material market and well-equipped equipment system. Through these two aspects, we can offer a more reasonable pricing for you.

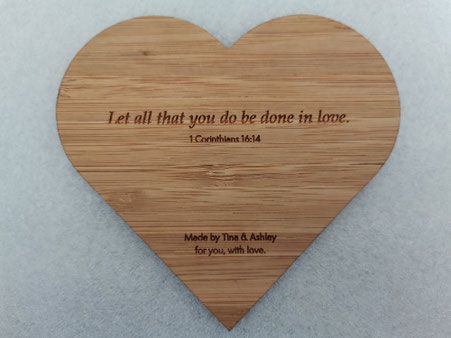

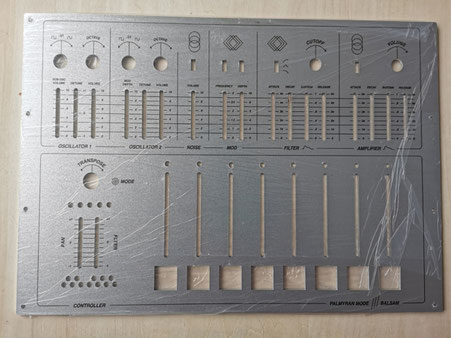

Besides laser cutting, laser engraving and laser marking are also among our primary services. Laser engraving is good producing method for wood materials, such as solid wood, plywood, and MDF which for fill engraving and single-line engraving. It is also suitable for normal engraving and deep laser etching of acrylic as well. As for laser marking, it is typically targeted at metal materials, such as marking on stainless steel surfaces for white or black effects, marking on alumina oxide, and marking on brass surfaces and so on.

To meet the marking requirements of different materials, we own various types of laser engraving machines. Carbon dioxide laser engraving machines are specifically designed for non-metal materials engraving, such as wood or acrylic. For ordinary metal materials and some plastic materials such as PC, ABS, PVC and more, precise marking can be achieved using fiber laser marking machines.

UV printing is different from some traditional methods like spray painting, digital printing, or screen printing. This process allows printing on various types of plate materials. We often print patterns on plywood, medium-density fiberboard, bamboo board, and acrylic board. Furthermore, it can even be used for printing on metal surfaces such as stainless steel or aluminum plates. UV printing is not limited to hard substrates but also suitable for flexible materials, such as fabric, soft plastic sheet and papers. Additionally, UV printing technology enables printing on curved surfaces of products like cups and golf balls.

We have incorporated this technology into our production, allowing us to offer UV printing, laser cutting, and laser engraving services in one stop, providing greater diversification for your products. We accept bulk orders and can also cater to small-lot UV printing requests.

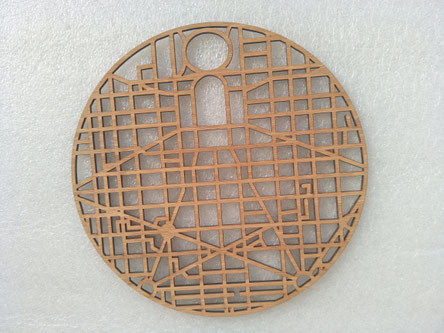

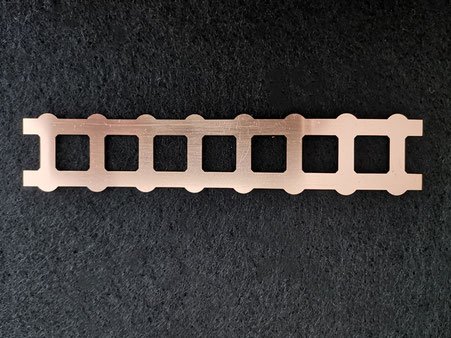

Wood is a commonly used material for laser cutting, generally classified into solid wood and artificial composite/engineered wood. Solid woods, for example, walnut, oak, pine, sapele, and cherry wood are readily available in the market. Engineered wood, such as plywood, MDF (medium-density fiberboard), and bamboo board, are all derived from natural wood and processed into composite wood materials through advanced techniques.

The wood products we laser cut have excellent quality, with clear and beautiful wood grain on the front side, free from burn marks, eliminating the need for secondary polishing. The backside mostly remains free from burn marks or may have very shallow ones. As we employ specialized laser engraving machines, the engraved patterns on the surface are clear, delicate, and capable of showcasing intricate details.

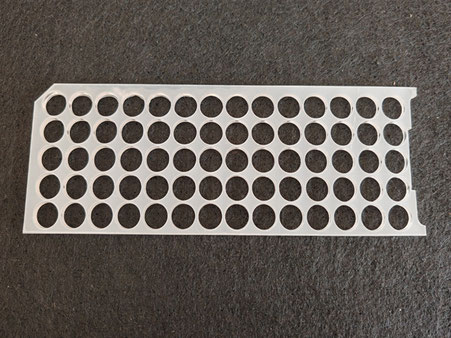

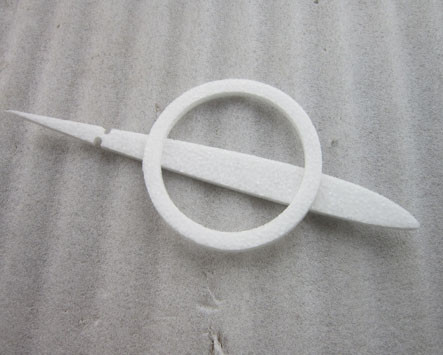

The commonly used laser cutting plastic materials are acrylic, ABS sheet, POM, HDPE, Mylar board, PC, PS, PE, and dual-color board.

Among them, acrylic is one of the plastics that perfectly combines laser cutting and engraving. The processed edges are clean and smooth, achieving color consistency with the acrylic sheet without discoloration or fading.

Other plastic materials also possess unique characteristics, resulting in distinct features of the processed products.

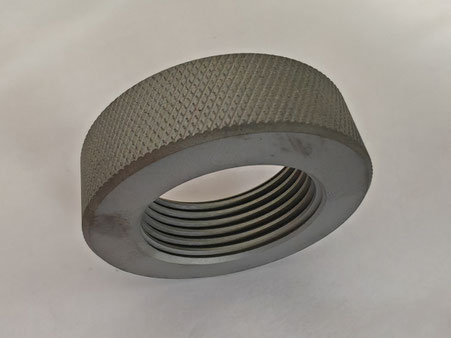

We have high-powered metal laser cutting machines with a large cutting tables measuring three meters by six meters. It is specialized in cutting various types of metals, such as stainless steel, mild steel, weathering steel/Corten steel, galvanized steel, brass plate, bronze, copper plate, aluminum, and titanium plate, etc. They are capable of cutting both thick and thin plates, achieving high-precision cutting even with metal foils.

Laser cutting is inseparable from materials. We have a wide range of wood processing materials available, such as solid wood boards, plywood, MDF, bamboo boards, and veneer faced boards. Additionally, plastic materials like acrylic sheets, PC sheets, ABS sheets, and HDPE are also essential. Moreover, commonly used metal materials including stainless steel sheets, aluminum sheets, carbon steel sheets, copper sheets, and brass sheets can meet customers’ normal needs. Please refer to the material-specific page for more details. Due to the diverse range of materials that can be processed by laser cutting, some materials may not be frequently used, so we generally only stock conventional materials. If we are unable to provide the materials you need immediately, there is no need to worry because we have various types of material markets nearby. Under normal circumstances, we can timely procure the materials you need to meet your customization requirements.

In addition to laser cutting, engraving, and UV printing, we also offer a range of other processing services.

For example, sheet metal processing (bending, threading, countersinking), CNC machining for precise shaped parts. Also, medical device components, and machine accessories.

In addition, laser cutting for stainless steel capillary tubes, precision tubes, and bright tubes (cutting, perforating, slotting).

And various surface treatments. Such as vibratory polishing, gold plating, nickel plating, galvanizing, anodizing, electrostatic powder coating, electrophoresis, and spray painting.

Moreover, we offer customized packaging solutions. We can assist in sourcing and purchasing specialized packaging boxes for your processed products. As well as sourcing and procurement of related accessories for customized products if suitable manufacturers or channels are not available. Rest assured, we will always strive to provide our customers with high-quality products and services.

Laser cutting technique is very suitable for custom products without quantity requirement. It is saving time, saving trouble and saving money. Just uploading the vector files to laser cutter, a few minutes later, your wonderful ideas come into reality.

If we are careful to observe the surroundings, you can find out many places with laser cutting products to serve our society. Such as, machining spare parts, festival decorative crafts, Christmas gits. And floor/door/window decoration panels. Or wooden name cards for business, nice invitation cards for wedding; engraved wood book covers, custom boxes, etc.

Hopeland provides best laser cutting services for customers from all over the world. And we hope to build long-term cooperation with each other. No matter you are company or individual, we will do much better to move your projects with good results.

It’s our pleasure to provide high quality laser cutting services with competitive costs for customers from different fields. No matter you are designer, engineer or sales, We will provide you the competitive quotation, the good services, and the fast delivery time.